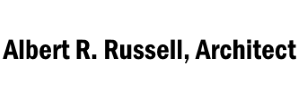

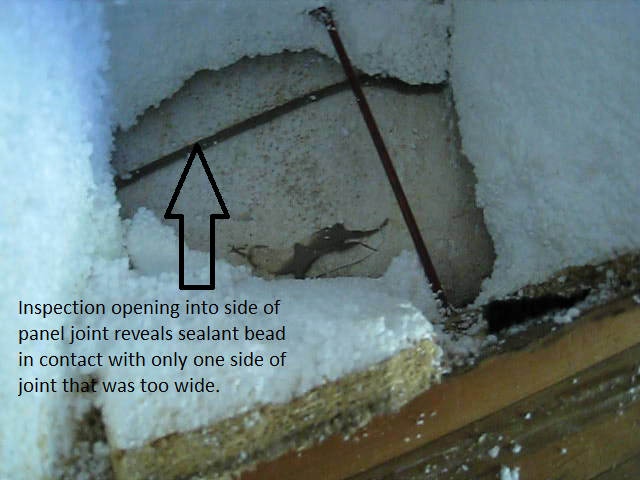

Structural Insulated Panels (SIP) have enjoyed growing popularity as interest in building energy conservation has increased. With its large, prefabricated, factory insulated panels, SIP construction offers nearly continuous insulation, fewer joints than conventional frame construction with stud-cavity insulation, and possibly speedier construction in the field. A SIP thickness equal to a sheathed 2×6 wall can offer a thermal value about 1.5 times the value of the conventional, fiberglass insulation in the 2×6 wall, and the increase in insulation continuity adds even more comparative thermal value than the label can document. However, the excitement over SIP thermal value and speed is not always accompanied by a sufficient level of attention to effective moisture management. SIP panel joints and connections with doors, windows, and other penetration must be made air tight. Panel joints that rely on a bead of caulking to seal the gap must be tight enough for the bead of caulking to close the gap; if the joints are too wide (as in the top 2 photos below), air can leak through the panel joint and lead to condensation and other moisture related problems. Also, SIP panel skins like OSB (oriented strand board) are typically not impervious to water, so they need to be protected with a properly lapped and flashed exterior weather barrier / drainage plane that will keep water away from the panel skin. Omitting the weather barrier can lead to destructive rot when weather-related water penetrates siding (as shown in the third photo below). Moisture management also extends to humidity control: an effective mechanical system that maintains a non-damaging humidity level 24/7 is necessary in a building that houses a swimming pool. And in that kind of building, a moisture sensitive material like gypsum board should not be used as a ceiling, especially where it is attached directly to the underside of SIP roof panels with an OSB interior face (see resulting SIP damage in bottom photo below). So, SIP building performance depends on effective moisture management, including properly fitted and sealed joints, protection of SIP panel skins from damaging exterior and interior moisture, and adequate interior humidity control.

CAUTION

The content provided on this site and in the Posts is intended to be entertaining, thought-provoking, and educational. It is not intended as direction or recommendations for the design or construction of any specific building project. The information is provided in good faith but without assurance as to its completeness, accuracy, or suitability for any particular purpose. If you are considering using information provided on this site, you are responsible for verifying its appropriateness to your needs, and you assume all risk for its use.

Recent Posts

Archives

- March 2023

- January 2023

- November 2017

- May 2017

- April 2017

- February 2016

- January 2015

- December 2014

- September 2014

- August 2014

- June 2014

- February 2014

- January 2014

- December 2013

- July 2013

- June 2013

- January 2013

- March 2012

- February 2012

- November 2011

- September 2011

- December 2009

- November 2009

- October 2009

- May 2009

- April 2009

- March 2009

Leave a Reply